Automations

Praber is your specialized technical partner for undertaking automation plans for your forging production processes, meaning it can advise you and then install automation or systems to increase productivity and excel in quality.

- Automotive and motorcycle

- Bolts and nuts

- Hydraulics and plumbing

- Heating

- Fittings

- Housewares

- Coins and minting

The entire design and manufacturing process is internal to Praber, with a dedicated company division (laboratory, warehouses, documentation, and resources).

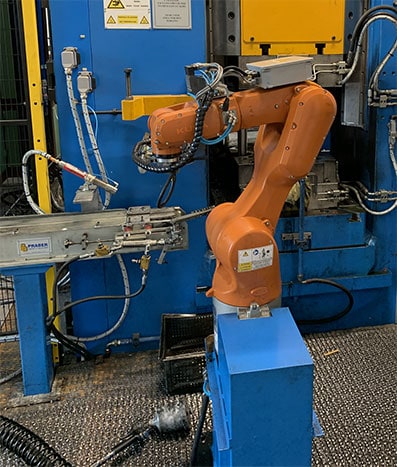

Loading systems and robotic arms.

Praber is a benchmark in the industrial automation sector.

We specialize in the design and production of advanced systems for loading and unloading presses, for both hot forging and cold forming, in addition to solutions with anthropomorphic robots and automated arms.

With extensive experience in the field of industrial automation, we are constantly committed to offering cutting-edge solutions that improve the efficiency, safety, and productivity of your manufacturing processes. Our customized systems for loading and unloading presses are designed to optimize machining operations, reduce machine downtime, and maximize the overall yield of your production line.

What sets us apart is the use of anthropomorphic robots, automated arms, and highly customized systems tailored to your specific needs. These devices are characterized by extraordinary precision, flexibility, and reliability, allowing for efficient handling of a wide range of materials and components with extreme accuracy, ensuring consistent and uniform quality of your products.

Our team of expert engineers and technicians collaborates closely with you to understand your specific needs and design customized solutions that seamlessly integrate into your production environment. From the initial analysis to commissioning and after-sales support, we are committed to providing a comprehensive and reliable service at every stage of the process.

Relying on Praber means investing in cutting-edge automation solutions that increase your competitiveness in the market and allow you to reach new levels of success. If you are interested in improving your production, do not hesitate to contact us for a personalized consultation on our automation solutions.

Die lubrication.

The high-pressure die lubrication system allows for perfect and constant metering of the lubricant, thanks to the graduated scale on the lubricant opening knob, thus avoiding costly waste.

The adjustment scale can be used as a reference in orders for the immediate regulation of the lubricant quantity, avoiding wasted time for adjustments and production rejects due to incorrect metering.

The system allows the use of graphite-rich mixtures up to 1200 CST at 40°C, significantly improving the quality of the forged part.

The pump located in the tank ensures that the oil mixture is always in continuous suspension; furthermore, the container is equipped with an additional manual stirrer on the lid.

The perfect metering of the oil significantly improves the lifespan of the die with regard to sedimentary oil deposits (fewer stoppages for sandblasting).

The excellent flow rate of the oil vaporization valves allows for effective cooling of the pins on piercing tools, enabling better sliding and longer lifespans.

If correctly adjusted, the metering system allows for a 25%-30% saving in the amount of lubricant normally used.

* Required fields