Services

- Design and development of customized presses based on customer specifications.

- Customized automation solutions to optimize production efficiency.

- Analysis of production needs and consulting for the implementation of new technologies.

- Feasibility studies and design of innovative solutions.

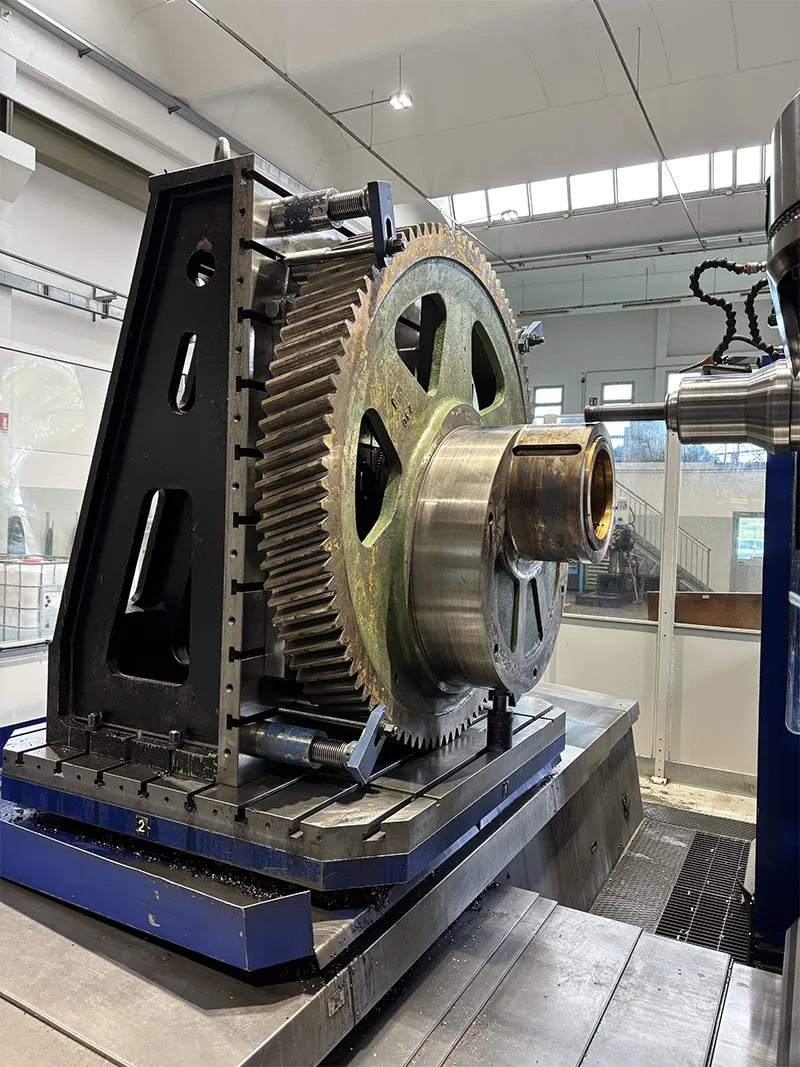

- Manufacturing of presses and automation systems with cutting-edge technologies.

- Installation and commissioning at the customer’s facilities.

- Integration of automation systems to improve productivity and reduce downtime.

- Programming and configuration of software for the control of presses and automation systems.

- Training programs for operators and technical personnel on the operation and maintenance of equipment.

- Support in the management and optimization of production processes.

- Preventive and corrective maintenance services to ensure operational continuity.

- Technical support and remote assistance to promptly resolve any issues.

- Modernization of existing presses with new technologies and features.

- Retrofit solutions to enhance the efficiency and safety of outdated equipment.

- Supply of original components and spare parts to keep equipment in optimal working condition.

- Spare parts warehouse to ensure fast delivery times.

- Consulting services to ensure equipment compliance with current safety regulations.

- Installation of safety and protection devices.

- Analysis of existing production processes to identify areas for improvement.

- Implementation of solutions to increase productivity and reduce operating costs.

These services enable the company to offer comprehensive and integrated solutions, helping clients improve their competitiveness and effectively respond to market challenges.

Support

Business division dedicated to design, spare parts, support, and training,

as well as the development and provision of all upgrade packages for the installed machine base.

For every installed press and screw press, an updated archive is maintained, containing technical drawings, applicable upgrade packages, and a complete list of all installed components, including supplier details.

A rigorous system classified by machine serial number always allows for the traceability of the installed configuration, thanks especially to the in-house design service.

This is the value of Praber’s know-how!

Support can be provided on-site or remotely through the “tele-service” connection, which our machines are equipped for. This enables prompt intervention and ensures rapid resumption of production.

* Required fields